Table Of Content

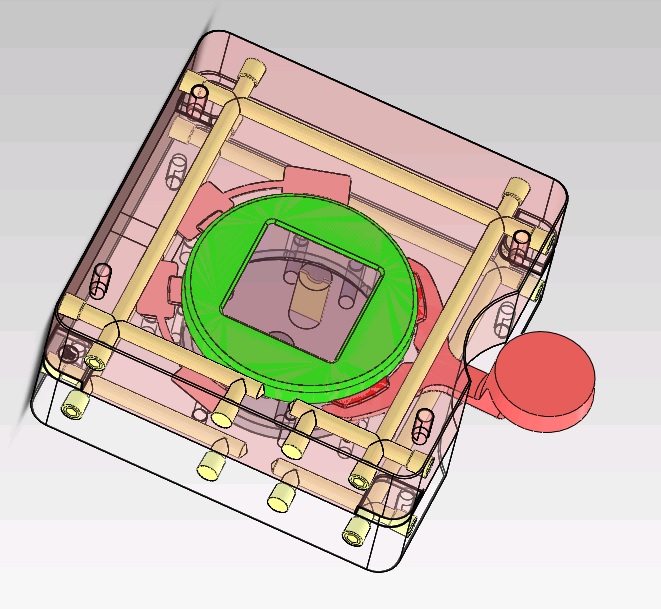

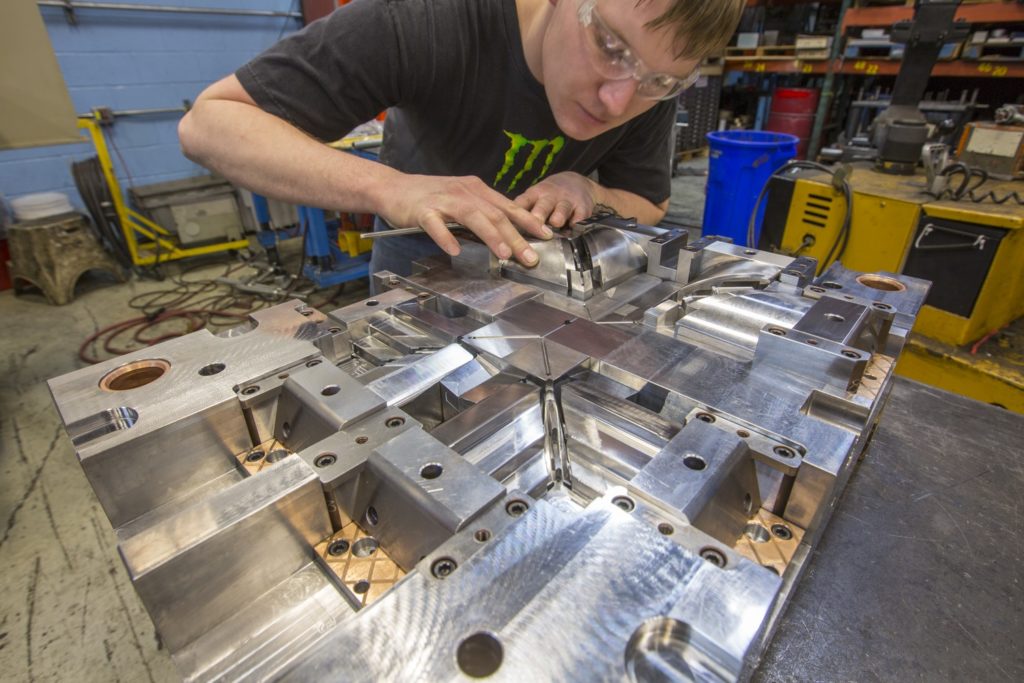

The tool builder is given the tool design specifications for mold construction. Final adjustments and modifications are done in-house, with special attention given to manufacturability and critical dimensional requirements. Draft angles refer to the degree of taper added to a part’sdesign, which allows it to eject from the mold quickly. A draft angle helpsprotect surfaces during ejection and minimizes mold damage during removal. The wall thickness of a part is essential in ensuring itsstructural integrity. A suitable thickness should be consistent across thepart, giving it sufficient strength and rigidity while avoiding problems suchas warping or sink marks.

Common Molding Defects

Once these are reviewed and approved, the detailed design is finalized. The school has received $50,000 in grants from the Ahmanson Foundation to participate in the program, Moran said. The point of the project, said Holbert, is to one day enable the space station to 3D-print replacements for things that break on board, such a fasteners or tools, rather than having to ship them from earth. 4.We will decide the type of injection system, conduct Moldflow analysis, and confirm the gate form, location, and numbers.

The Basics of Injection Molding

Proper placement of cooling channels in mold walls to circulate water are also essential for cooling to create a final product with homogeneous physical properties, resulting in repeatable product dimensions. Uneven cooling may result in defects called “hot spots”—areas of weakness that affect repeatability. Prior to ejection from the mold, injection molded parts are cooled down from manufacturing temperatures so that they hold their shape when ejected. During the part cooling step of the molding process, changes in pressure, velocity and plastic viscosity should be minimized to avoid defects. This feature can have major effects on the cost, production speed and quality of the final parts.

EARRINGS MOLDS

Unless the shape of the product is limited, other ejector pins must be used. Generally, cylindrical ejectors are used, and elongated ejector pins with a diameter less than 3mm should be avoided. 2.The reset rod (return rod) must be set in the ejection system to help the ejector rod return.

Wall Thickness

The main restrictions on Injection Molding usually come down to economics, as high initial investment for the mold is required. Also, the turn-around time from design to production is slow (at least 4 weeks). During the cooling process, if walls are an inconsistent thickness, the thinner walls will cool first while the thick walls are still solidifying. As the thick section cools, it shrinks around the already solid thinner section.

Mosquito Net Buying Guide

Gates are often located in open features such as windows or voids where other parts are inserted. If the edges of the part are critical for mating to another part or are cosmetically important, the designer must specify that the gate vestigial be machined to their specifications. Otherwise, the remaining material could interfere with mating parts or be cosmetically unacceptable. This guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is optimized for molding. External undercuts are the easiest and most cost effective as we accommodate through pin-actuated side-actions.

The right manufacturing process for a certain part is largely dependent on the development criteria. In some cases, multiple production processes can be used to create any given design. As a rule of thumb, choose the process that can produce the given part with the required quality, at the lowest costs, while fulfilling the rest of the development criteria.

The purpose of the injection unit is to melt the raw plastic and guide it into the mold. In the mid 1950s, the invention of the reciprocating screw single-handedly revolutionized the plastics industry. The reciprocating screw solved key issues with uneven heating of the plastic that previous systems faced, and opened up new horizons for the mass production of plastic parts. In cases that are not adaptable for side-actions, we can use manually removed inserts. These are mold components that are greater than a half-inch cube and are loaded by an operator into the press before it closes. After the part has been molded, the part is ejected along with the insert.

Indiana bridge breaks the mold with its unconventional design - Construction Specifier - The Construction Specifier

Indiana bridge breaks the mold with its unconventional design - Construction Specifier.

Posted: Thu, 07 Mar 2024 08:00:00 GMT [source]

The injection molding process

When the two are closed, space between is the part cavity where the molten plastic fills. There are different mold types like hot runner molds, two/three-plate molds, high/low cavitation, unscrewing molds, cold runner molds, family molds, and insulated runner molds. Currently, industries are trying to apply sustainable measures in their manufacturing as it is a global trend and this affects the process since they have to change some aspects to fit this idea. Injection molding companies have to find ways of reducing their carbon footprint. This section provides a brief overview of mold-making techniques for different manufacturing processes. Follow our links for in-depth guides and the step-by-step workflow for each process.

Features with undercuts (such as the teeth of a thread or the hook of a snap-fit joint) may not be manufacturable with a straight-pull mold though. This is either because the mold cannot be CNC machined or because the material is in the way of ejecting the part. If more complex geometries are required, then retractable side-action cores or other inserts are required.

Rapid prototyping techniques such as3D printing will remain essential in mold design, enabling designers to rapidlycreate and test molds before mass production begins. Computer Numerical Control(CNC) machining is a viablealternative to traditional metal molds, providing high-temperature andwear-resistance products. Manufacturers will experience more efficient andcost-effective production processes by integrating advanced technologies intomold design considerations. In fact, packaging is the largest market for injection molding.For example, bottle caps are injection molded from Polypropylene. There are several factors that may affect the quality of the final product and the repeatability of the process. The main economic restriction of injection molding the the high cost of tooling.

No comments:

Post a Comment